- Tel:+86 10-57536875 ext.801 Copyright DeMer-River 京ICP备案14015669号

-

Your present position: Home >> Products >> Hardness Tester >> Portable Hardness Tester

FEATURES | ||

- | Impact type hardness tester | |

- | Build in Mini-printer. | |

- | 320 x 240 LCD display with backlight | |

- | For most metals | |

- | Based on the Hardness HL value, conversion can be performed to HRB, HRC,HV, HB, HS and Tensile strength | |

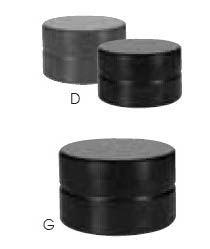

- | Impact devices D, DC, DL, C,D+15, and G are available for special applications | |

- | Test at any angle, even upside down | |

- | Lower and upper limits setting with low-high display judge | |

- | High accuracy ±0.5% | |

- | USB output for both recharging and data transfer to PC | |

| - | Extended memory in 1750 dates | |

| - | Works on 4 AA rechargeable batteries with working 48 hours continuously | |

- | Auto shutdown after 2 minutes | |

- | Conforming to ASTM A 956 | |

| Specification | ||

| Hardness Parameter | HL, HRC, HRB, HV, HB,HS | |

| Measuring Range | See table below | |

| Display | 320 x 240 LCD with backlight | |

| Display functions D | Hardness Scale, Hardness Value, average value, impact direction, Max/Minvalue, Material, battery life, date, instruction | |

| Accuracy | Within +/- 0.5% (at HLD=800) | |

| Memory | 1750 group | |

| Standard Impact device | D | |

| Optional Impact Device | C / D+15 / DC / DL /G | |

| Output | USB | |

| Testable work piece | - | Thickness coupled: Minimum 3 mm or more (Except with Impact device G:10mm) |

| - | Mass: 5kg or more (2-5kgon solid support ,﹤2kgwith couplant paste) | |

| - | Surface roughness: Ra 10 | |

| - | Radius (convex/concave): Rmin=30mm or more (﹤30mmwith support ring ) | |

| - | Test Points: 5mm or more from the edge of the sample, 3mm or more to each of thetested points. | |

| Battery type | 4 x 1.25v rechargeable battery | |

| Operating temperature | -20℃ ~ +50℃ | |

| Dimensions | 215mm×140mm×45mm | |

| Weight | 700g |

| Range reference |

Material | HL | HRC | HRB | HB | HS | HV |

ST & Cast ST | 300-900 | 20.0-68.0 | 38.4-99.5 | 80-647 | 32.5-99.5 | 80-940 |

CWT Steel | 300-840 | 20.4-67.1 | 80-898 | |||

Stainless | 300-800 | 19.6-62.4 | 46.5-101.7 | 85-655 | 85-802 | |

GC Iron | 360-650 | 90-334 | ||||

NC Iron | 400-660 | 131-367 | ||||

Cast Alum. | 174-560 | 20-159 | ||||

Brass | 200-550 | 13.5-95.3 | 40-173 | |||

Bronzes | 300-700 | 60-290 | ||||

Copper | 200-690 | 45-315 |

Standard Delivery | |||

- | Main unit with Impact device D |  | |

- | Build-in printer | ||

- | Test block with HLD value | ||

- | Software and USB cable | ||

- | AC adapter/charger | ||

- | Small supporting ring | ||

- | Calibration certificate | ||

- | Cleaning brush | ||

- | Carrying case | ||

- | User manual | ||

Optional fittings

|

|

|

| Probe | Impact body |

|

|

| Hardness Block | Support Rings |

| |

| Connect cable |